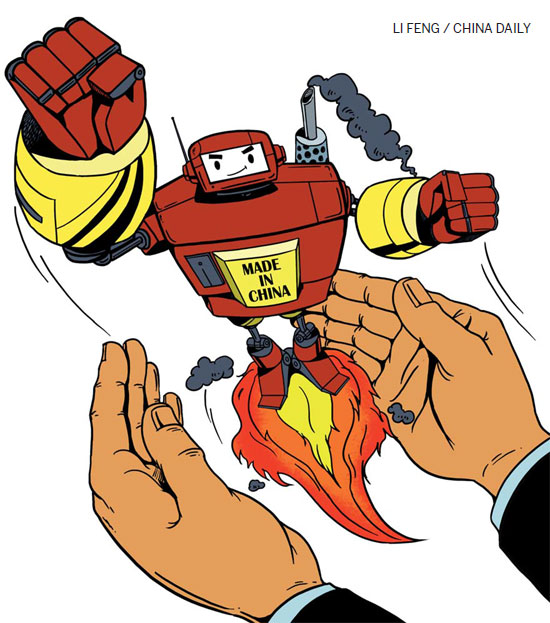

Booming robotics a platform for advanced manufacturing

China is about to triple the annual production of robots in manufacturing to 100,000

The emerging robotics industry is booming in China. The move to advanced technology is aligned with the government's Made in China 2025 strategy, which is aimed at upgrading China's manufacturing base. In turn, the development plan for the robotics industry, released in April, seeks to accelerate Chinese robotics with breakthrough products over the next five years.

Nevertheless, critics argue that the emergence of the Chinese robotics industry is being sustained by subsidies doled out by local governments, and they question whether the industry would be able to survive on its own in the face of global competition.

China's robotics boom is often explained by rising costs and aging demographics, yet they are only part of the big picture. In the mainland, the robotics boom has been fueled by several forces, including demographics (growing engineering talent, the declining factory-age workforce, and the aging workforce), increasing costs (rising wages, costs of training and housing), and favorable financing (low-cost loans, factory incentives and investment by foreign tech giants that manufacture in China).

Furthermore, the boom has been driven by government policies (central government encouragement, local government mandates, and tax credits), rising quality requirements (ramping up automakers for export), and the emergence of early adopters in China (more capital-intensive companies and an expansive middle class with disposable income).

Not so long ago, the major robotics markets comprised Japan, the United States, Germany, South Korea and China, which had a combined share of 70 percent. But in 2014, sales of industrial robots soared in China, and it became the largest market for robotics with a 25 percent share of the global total. However, sales remained dominated by foreign giants, such as the Swedish-Swiss ABB, Japan's Fanuc and Yasukawa Electric, and Germany's Kuka.

Last year, Japan still dominated the manufacturing of global industrial robots, with some 60 percent of the global total. But by the end of the current year, China hopes to overtake Japan. Chinese robotics pioneers, including Shenyang Siasun and Ningbo Techmation's subsidiary E-Deodar, have been scaling up fast, and China is about to triple the annual production of robots in manufacturing to 100,000 in five years and sell over $4.6 billion worth of service robots by 2020, thanks to surging demand in healthcare, education and entertainment.

This year, China's growing robotics industry turned to acquisitions, as evidenced by the acquisition of Michigan-based Paslin by Wanfeng Technology, Siasun's planned acquisitions, and Chinese venture funds' investments in robotic ventures in Russia, Israel and Silicon Valley.

However, due to its huge population, China still has a long way to go. The density of robots in the mainland is still low relative to the current leaders in robotics. China has about 36 industrial robots per 10,000 manufacturing workers, while Germany has 292, Japan 314 and South Korea 478. China's robotics industry therefore has potential to grow five to 10 times in the medium-term.

Critics say subsidies may contribute to the rise of inefficient robotics companies. This argument is not invalid, but it misses the point. If China did not try to scale up its industrial capacity in promising emerging industries, it would remain just a buyer and dominated by foreign companies with profits continuing to flow out of the country. That was the case in mobile networks and smartphones until the rise of Chinese industry pioneers such as Lenovo, Huawei and Xiaomi.

Scaling up emerging industries requires innovation, which has accelerated fast in China since the early 2000s. Today, R&D as a share of the Chinese economy exceeds 2 percent, which is higher than in Europe. In cutting-edge megacities, such as Shenzhen, the ratio is closer to 4 percent, almost as high as that of South Korea or Israel, the world's R&D leaders.

In years to come, China will still continue to dominate many industries as a low-cost player, thanks to its large population base. But it is also rising in advanced manufacturing, such as robotics, as a major producer. That is vital for China's economic rebalancing, which is transforming the mainland into a global R&D hub.

The author is a guest fellow at the Shanghai Institutes for International Studies. The views do not necessarily reflect those of China Daily.